Craftsmanship

How a Machine is Designed is Pivotal to How it Performs

The design of a machine is pivotal to its performance, especially in the realm of high precision machining. It determines the machine's ability to achieve tight tolerances, maintain stability, and deliver consistent and accurate results. A well-thought-out and meticulously engineered design specifically tailored for high precision machining can enhance productivity, minimize errors, and enable the machine to operate at peak performance levels.

- Kitamura’s “Mycenter” Machining Centers are built on Kitamura’s premise of TGA-True Geometric Accuracy.

- Kitamura designs and builds its machines precisely, from the ground up, no short cuts in design and manufacture.

- Hand scraping of all mounted surfaces requiring assembly in order to provide the full surface contact and proper alignment necessary to ensure exacting parallelism and perpendicularity

Accuracy – Hand Scraping

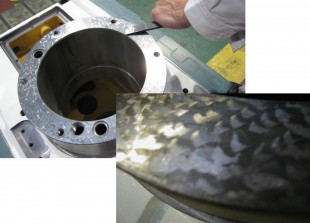

Accuracy in machining is a paramount requirement, and our commitment to achieving exceptional precision is evident through our meticulous hand scraping techniques. By employing some of the world's most experienced machine tool technicians, we ensure that all critical machine contact surfaces are hand scraped, resulting in perfect fit and optimal performance.

- Kitamura offers scraping in order to provide a high precision finish which cannot be accomplished by a machine.

- All critical machine contact surfaces are extensively and meticulously hand scraped by some of the world’s most experienced machine tool technicians.

- Machine components such as the spindle mounting surface shown fit perfectly each and every time.

Scraping for Geometry, Fit and Performance – Consistent Accuracies

When it comes to achieving precise geometry, impeccable fit, and exceptional performance Kitamura implements a proven process of "hand scraping" which as been a cornerstone for solid and accurate machine construction and assembly for years. The process of hand scraping can take anywhere from weeks to months for machine assembly depending on the size of the machine. Although time consuming, Kitamura carries on this time honored tradition because we want to build the highest quality machines, offering outstanding accuracies and machine tool life to our customers.

- Hand scraping and hand fitting of components allow for true geometric tolerances and long machine tool life.

- Consistent accuracies of ±0.002mm (±0.000079”) Full Stroke and ±0.001mm (±0.000039”) repeatability are able to be achieved as a result of timehonored hand scraping techniques.

- Kitamura Machining Centers NEVER use electronic straightness compensation to adjust squareness, parallelism or perpendicularity.

Built Solid by Design

We have an unwavering commitment to excellence in construction. By utilizing the highest-grade materials, we ensure the utmost quality and durability in the machining centers that we produce. With Kitamura, you can trust that you are investing in a machining center of unparalleled rigidity, reliability, and peak performance.

- Only the highest grade Meehanite Cast Iron is used in Mycenter Machining Center construction.

- Meehanite Cast construction coupled with our induction hardened, precision ground solid boxways provides the mass, stability and damping necessary to withstand extreme cutting conditions and deliver peak accuracy.

- Our manufacturing process is streamlined for optimum efficiency. All machine components are of the highest quality, and are assembled, inspected and tested by a team of dedicated craftsmen. You’ll find only the finest in a Kitamura.