Speed and Accuracy

High Speed, Ultra Precise Multi-Step Gear Driven Spindles

With Kitamura’s High-speed, ultra-precise multi-step gear driven spindles, you can experience cutting-edge technology in machining. These spindles incorporate 4-step gear driven technology, enabling spindle speeds of up to 20,000rpm. Not only do they deliver exceptional speed, but they also provide strong low-end torque and High-end fine finish capability, all in a single machine. What sets Kitamura apart is their original shockless drive mechanism, which effectively minimizes vibration resulting from milling cuts. Additional design features include:

- 4-step Gear driven technology, up to 20,000min-1 spindle speeds on #40 Machining Centers. World’s fastest

- Deliver strong low-end torque & high-end fine finish capability in one machine.

- Original shockless drive mechanism minimizes vibration from milling cuts

- Kitamura’s exclusive headstock design completely relieves the spindle bearings from heat generated at the motor allowing for tighter spindle bearing preload, ensuring optimum accuracy & rigidity

Ultra-High Speed Rapids on Solid Box Ways

When it comes to rapid speeds in machining, Kitamura’s system stands out as the world’s fastest on solid box ways. This remarkable performance is achieved through our patented technology. These innovative features include:

- World’s fastest at 60m/min (2,362ipm)!

- Patented high-precision twin ballscrew and dual feedback technology in horizontal machine models drive blazing feedrates and acceleration

- Pre-tensioned, fine pitch ballscrews and high-resolution servo motors deliver unparalleled accuracy

67 Million Pulse Encoder Technology

With our advanced 67-Million Pulse Encoder Technology, we bring you unmatched precision and accuracy in positioning. Elevate your machining capabilities with our state-of-the-art technology and enjoy:

- Outstanding positioning accuracy of ±0.000079”/Full Stroke

- Smaller incremental movements equal finer surface finishes

- Greatly improves cutting accuracy

- Roundness accuracy on circular cut to within 0.00012”

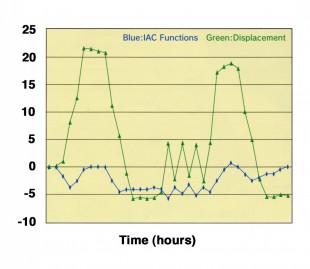

Kitamura’s Exclusive Intelligent Advanced Control System (IAC)

Our Intelligent Advanced Control System (IAC) is a game-changer in the realm of machining precision. With Kitamura’s IAC, you can confidently rely on a thermal compensation system that optimizes performance, maintains accuracy, and provides valuable insights into the temperature dynamics of your machining operations.

- Consists of a series of strategically located sensors and machine efficiency monitors

- Controls the effects of heat displacement in order to ensure continuous accuracy in machining

- Minimizes head displacement to less than ±5 microns

- Monitors temperature of machine and compensation and has the ability to graphically display temperature changes over a 24hr. period